People that know = stock that flow

Host: Jim and Terry Lindsay

Written by Anna Tickle.

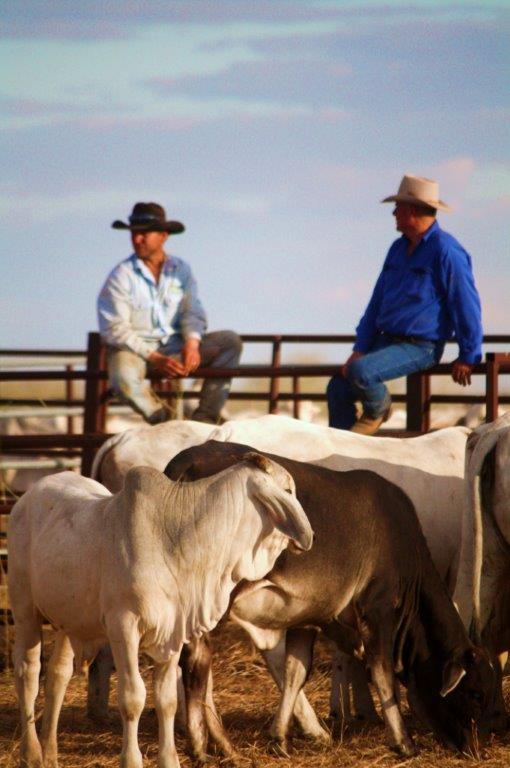

Stock being worked through the yards at an LSS School at Alice Springs.

Stock being worked through the yards at an LSS School at Alice Springs.

The interesting realm of Low Stress Stockhandling (LSS) can produce a mountain of monetary gain for the average livestock producer – and the proof is in the pudding, as you’ll read later. But perhaps the more emotive and lesser spoken about consequence is the personal satisfaction that can come from working with stock that cooperate.

It’s about having a two-way conversation, and according to Jim Lindsay it will work the same for cattle and horses, as it will for pigs, sheep, and even ducks. Whatever animal you produce, it seems LSS doesn’t discriminate (even if it does walk on two legs and quacks).

Jim and Terry own the company Low Stress Stockhandling Pty Ltd and Jim is one of a number of trainers who teaches its principles. Jim gratefully acknowledges the help he has had from American, Bud Williams, who has been the catalyst for change in stockmanship and stockhandling worldwide. The foundation for the teachings really gets to the core of basic animal instincts and science, explaining how an animal feels and thinks. Once handlers get the hang of that, it becomes easier to understand the implications of how we act, and what we say and don’t say around stock.

Jim says “where knowledge ends, violence usually begins,” and if we think about it, we know it’s true. It’s human nature to approach situations as predators. When something doesn’t go the way we plan it to, we don’t deal well with that, and however passive-aggressively we respond, those around us usually suffer.

“For people to understand why they need to change the actions they are taking around stock, they must first understand how an animal feels and thinks” Jim says.

Jim tells me certain instincts we have create problems when we are communicating with stock, so our biggest challenge is to take the ‘predator’ out of our body language.

Livestock producers work within a competitive space, and there’s a host of fixed costs to face long before stock leave the farm gate. Most of those can’t be changed, but there are certain things that can be done to improve the quality of the product. LSS is one of them.

One particular example Jim speaks about is a case study from the Tennant Creek area in the Northern Territory. Shrinkage, or the liveweight loss of cattle, commonly occurs during marketing and transportation. For one particular livestock producing operation, 12% loss via shrinkage from paddock weight to live export depot weight 900km away was common. They, like a lot of stock handlers employing LSS practices, decided something had to be done.

By modifying handling methods, the producers successfully reduced shrinkage to 8% for 3000 head of heifers, equating to a 14 kg each at $1.60/kg, totalling $22.40 per head. If you’re quick with maths, you’ll be able to see that meant $67,200; a prime example of LSS at its best.

But it’s not that simple. Before it is possible to get our animals in the right frame of mind we first have to get our mind and attitude right, and that’s one of the most thought-provoking points from my conversation with Jim.

If stock are in the right frame of mind, there will be many and varied benefits like higher feed intake, better pasture utilisation, less mis-mothering, and easier handling in all situations. That’s not even mentioning the efficiency improvements that result from satisfied handlers, and the benefits to animal welfare.

It doesn’t take a genius to see that all roads lead to greater productivity and ultimately, profitability.

They say a poor craftsman blames his tools. When it comes to stockhandling, some blame the yards. Others recognise that having infrastructure that promotes flow of stock is helpful, but not a necessity, which is a concept Jim stands wholeheartedly for.

His biggest point to me in this discussion is that the people – not the infrastructure – is what really needs our attention.

“The problem is that we keep designing facilities to suit people, rather than stock. While-ever this is happening, stockhandling practices will never improve.”

“We need to design facilities to improve stockmanship.”

Teaching LSS is a pivotal part of Jim and Terry’s life, and a significant commitment that sees them get ‘off-farm’ a number of times a year – something Jim tells me is crucially important for those that live on the land.

It’s intensive workshopping and no doubt draining, so it’s understandable that every now and then, Jim and Terry find themselves diverting a little way off the beaten track.

Later in the week, we’ll move further along the livestock production line and talk about Jim’s involvement in marketing livestock, and the three all-important facets of grass, money, and livestock.